Inflatable single and double packers ZI (28 - 102 mm)

The single and double packers are mainly used for cement grouting and permeability testing.

The basic components of single packers are,

dilatable element S

mounted on a metal structure

WT

with a sliding end

SE.

The cement grouting it’s done through the

central tube CP

made of stainless steel and inflation adapter

IA.

The length L

of the dilatable elements depends on the application requirements.

Standards lengths are :

●

L.300 mm for Ø28, 30 and 42mm packers

●

L.500 and 1000 mm for Ø28, 30, 42, 56, 72, 85, 102,130 and 170mm packers

●

L.1000 for Ø210, 255 y 285 mm packers

Other lengths are also available on request.

The single packers can be easily transformed into

ZI

Just unscrew the sliding end from the single packer and replace it with the

CE element, Complete the installation by screwing a standard

inflatable element S

(sleeve) and a

plug PL

on the lower part of the packer

The perforated

CE central element

from Ø 56mm to Ø 170mm consists of a compact and perforated tube, with a diameter identical to the whole packer assembly.

This design makes the double packer

ZI

extremely robust and the external flush O.D. is particularly well adapted to micropiles grouting and water pressure tests.

With Ø 28, 30 and 42mm packers, the narrow space between the two packer elements does not allow to use the same tubular design.

Here, the

CE element

consists of 4 pipes, two of which are used for inflation of the lower packer.

A special characteristic of these packers is that the injection zone (IZ) length remains constant after inflation.

Main specifications and dimensions of single and double packers

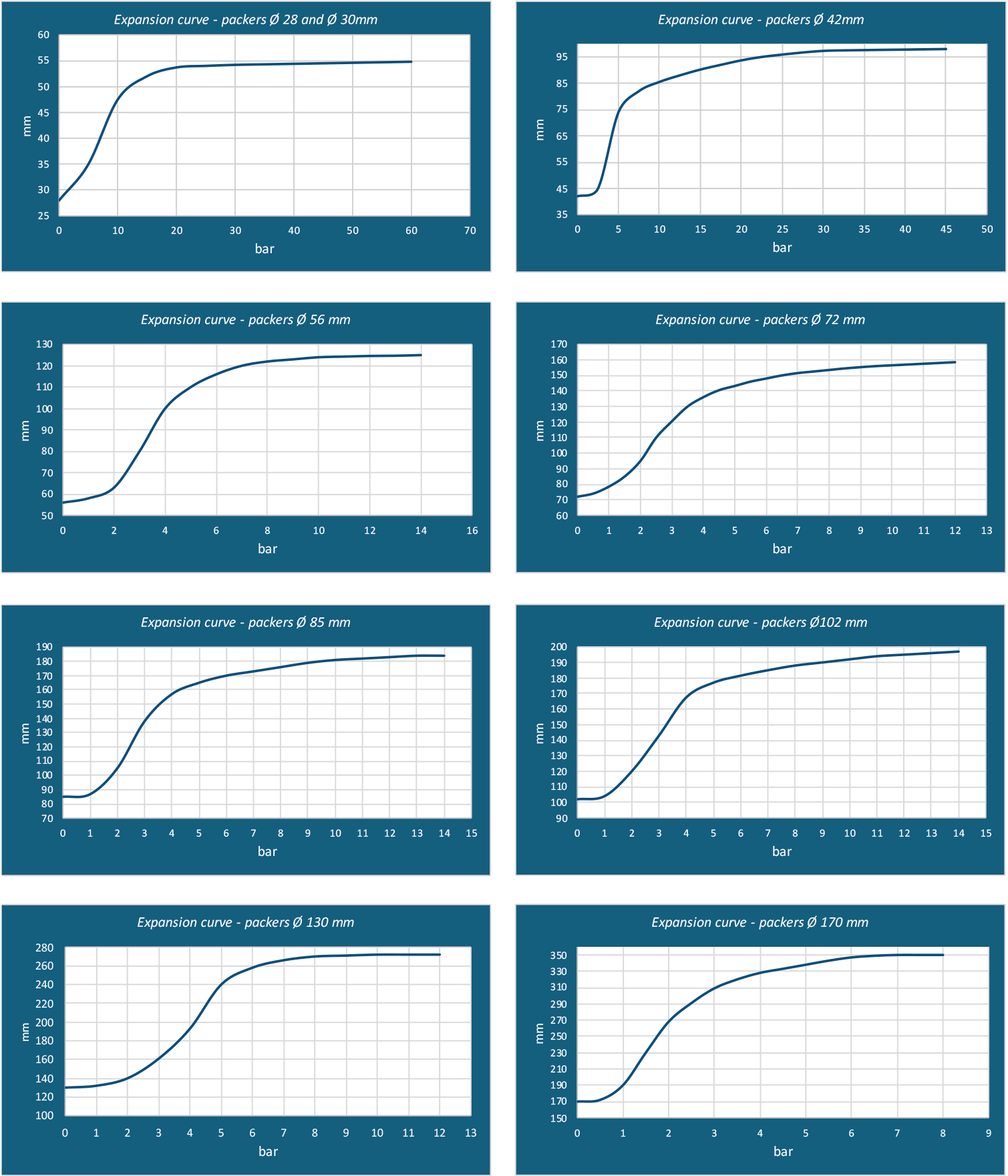

| Nominal diameter (mm) | Connection upper “TC” | Central tube “CP” Inner diameter (mm) | Expansion max. Diameter (mm) | Bore-hole Max.diameter (mm) | Inflation inlet “ IA” |

|---|---|---|---|---|---|

| 28 | 3/8" BSP | 8 | 55 | 50 | 1X 1/8" BSP |

| 30 | 3/8" BSP | 8 | 55 | 50 | 1X 1/8" BSP |

| 42 | 1/2" BSP | 17 | 98 | 90 | 2X 1/8" BSP |

| 56 | 3/4" BSP | 20 | 125 | 110 | 2X 1/8" BSP |

| 72 | 1" 1/4 BSP | 35 | 160 | 150 | 2X 1/8" BSP |

| 85 | 1" 1/4 BSP | 35 | 185 | 170 | 2X 1/8" BSP |

| 102 | 2" BSP | 53 | 200 | 190 | 2X 1/8" BSP |

| 130 | 3" BSP | 83 | 270 | 240 | 2X 1/4" BSP |

| 170 | 3" BSP | 83 | 350 | 320 | 2X 1/4" BSP |

All dimensions and characteristics are indicative only and may be modified without prior notice

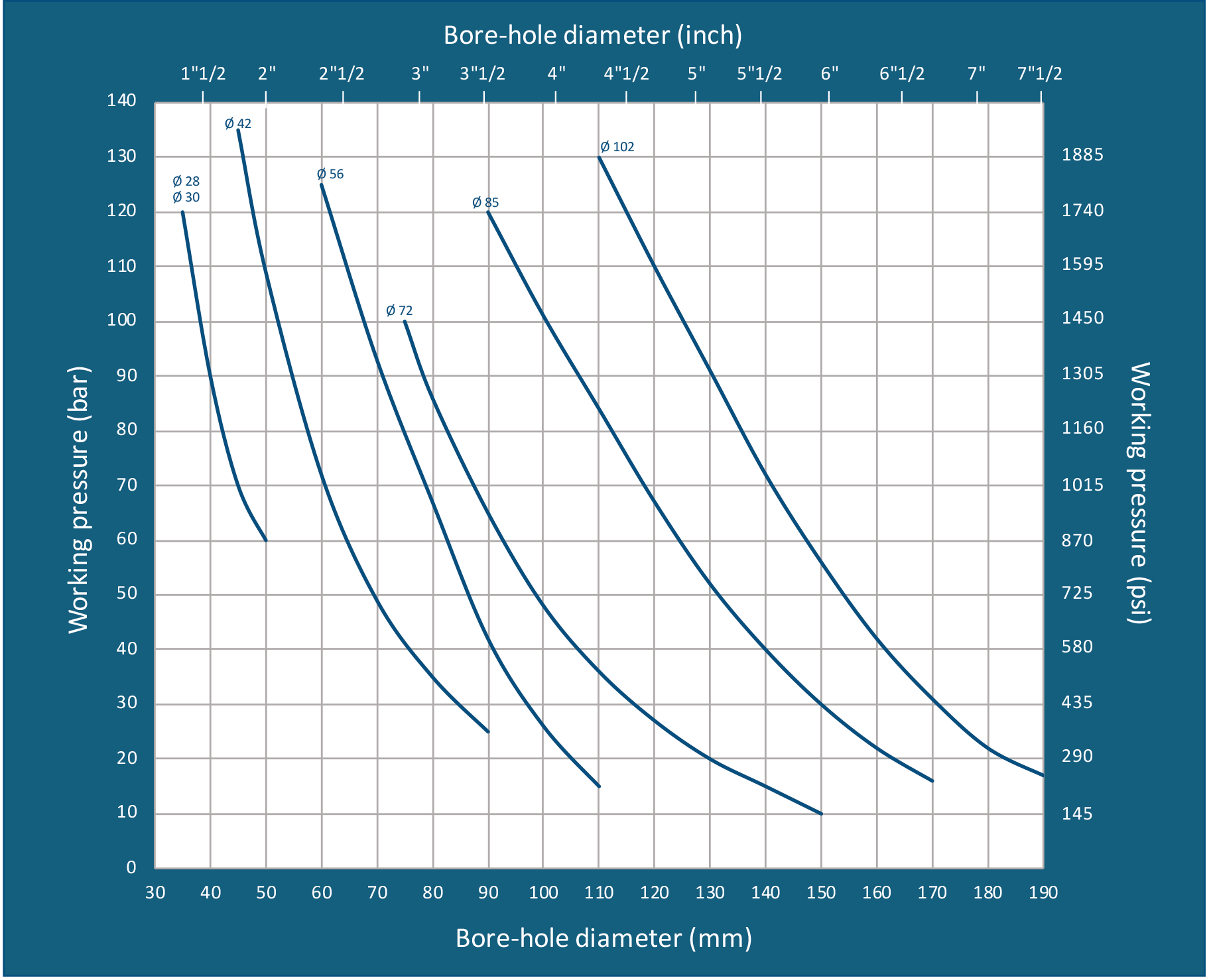

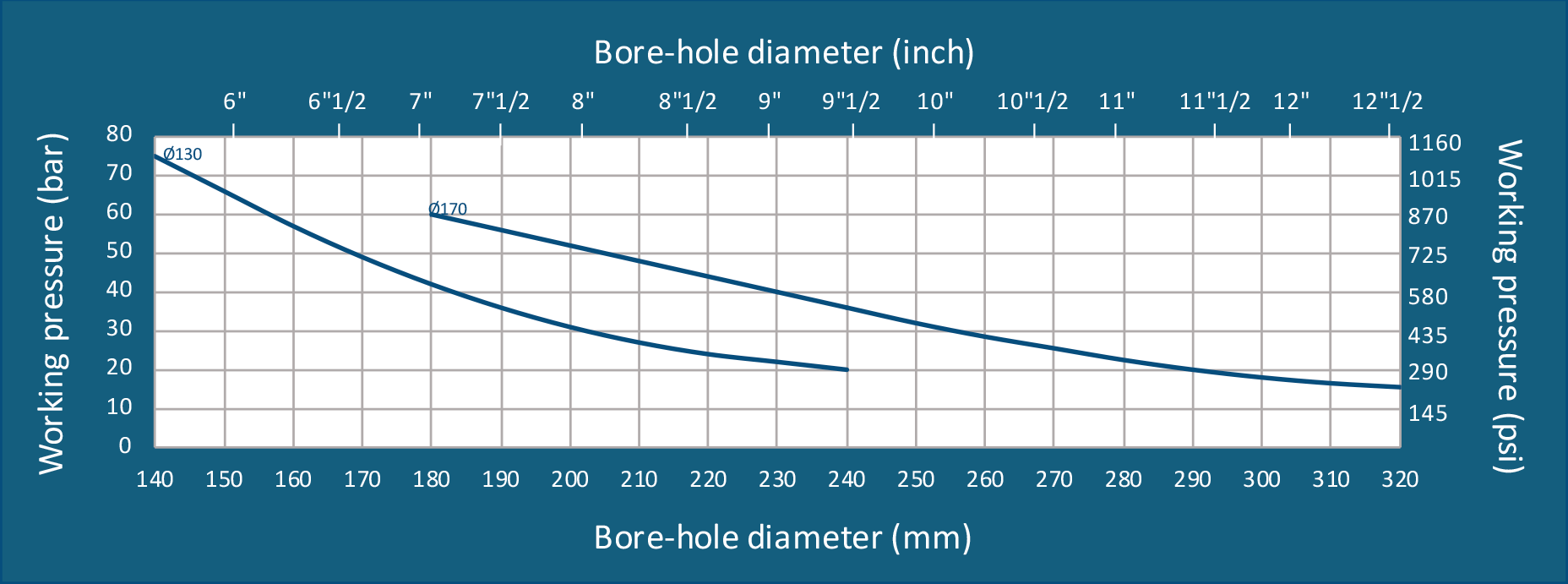

Working pressures